How To Create Purchasing Organization In Sap

In this post we will configure organization structure related to SAP S4 HANA Material Management. We will first define the various Organization elements related to SAP S4 HANA MM and then assign them to the related organizations elements.

This post is applicable for S4 HANA 1909 (& below versions) on premises decentralized & embedded as well as S4 HANA 2020 on premises decentralized & embedded version

Buy Now for USD 1.99

Pre-Requisite Configuration

Before continuing to the next block of "How to configure SAP S4 HANA Material Management Organization Structure in 5 minutes" and starting MM organization configuration, configuration of the below is recommended

Time needed:5 minutes.

How to configure SAP S4 HANA Material Management Organization Structure in 5 minutes

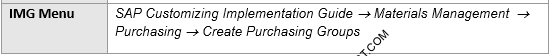

- Create Purchasing Groups

Four Purchasing Group (PA -Car Dealers, PB -Corporates, PC -Car Rental Companies, PD -Taxi Fleets) Created

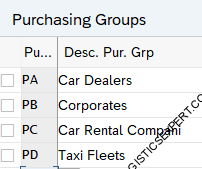

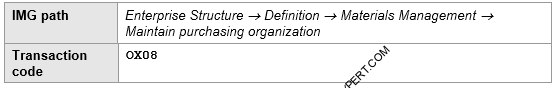

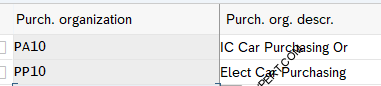

- Create Purchasing Organization

Two Purchasing Organization (PA10-IC Car Purchasing Org, PP10-Elect Car Purchasing Org) Created.

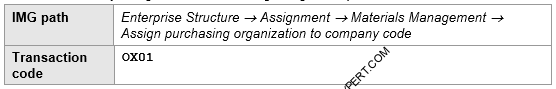

- Assign Purchasing Org to Company Code

Assign PA10 Purchase Org to PA10 Co. Code & PP10 Purchase Org to PP10 Co. Code

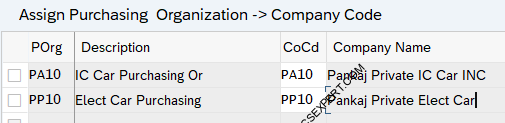

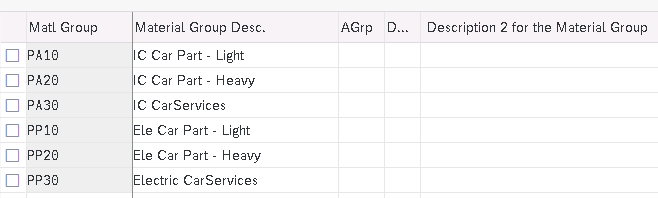

- Create Plants

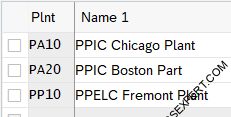

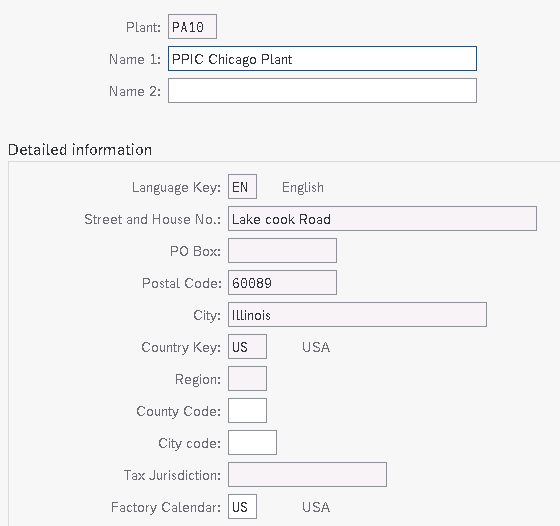

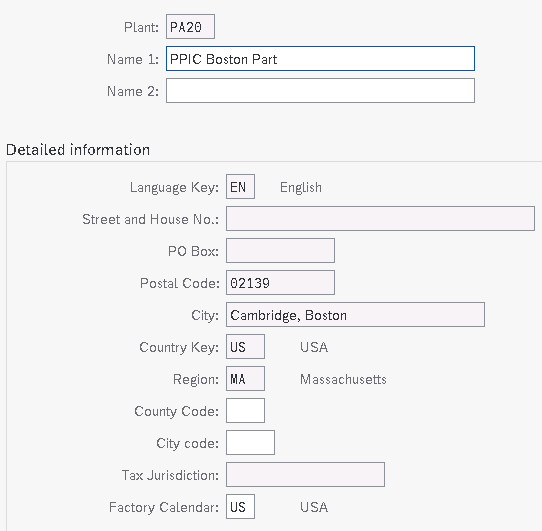

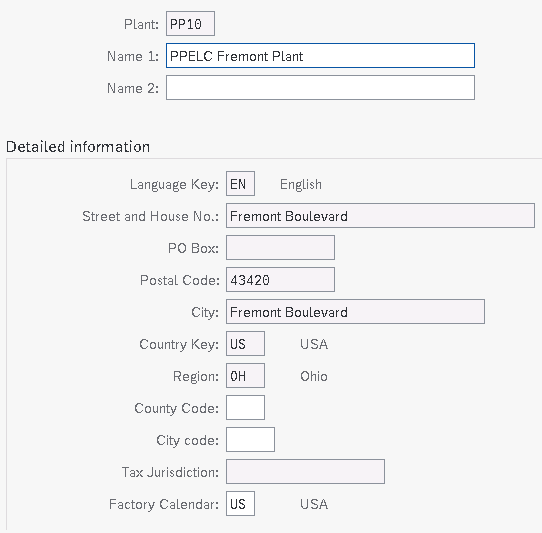

Three Plants (PA10-PPIC Chicago Plant, PA20-PPIC Boston Part, PP10-PPELC Fremont Plant) Created

- Define Plant Parameters

(Check respective section below for details)

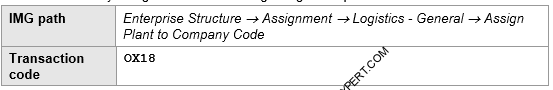

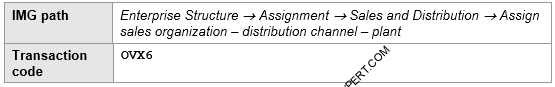

- Assign Plant to Company Code

(PA10 Plant ->PA10 Co. Code, PA20 Plant ->PA10 Co. Code, PP10 Plant->PP10 Co. Code)

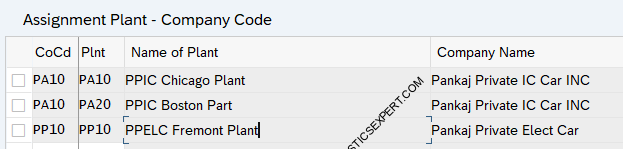

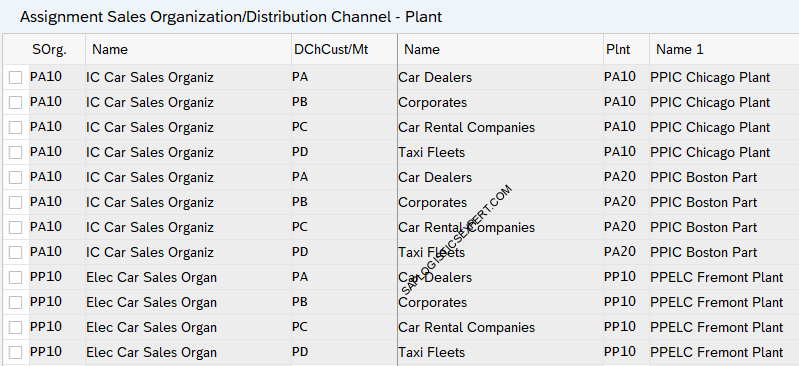

- Assign Sales Ord, Distribution Channel To Plant

(Both Sales Org assigned to 4 DCs and to respective plant)

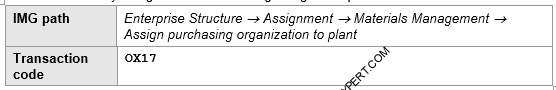

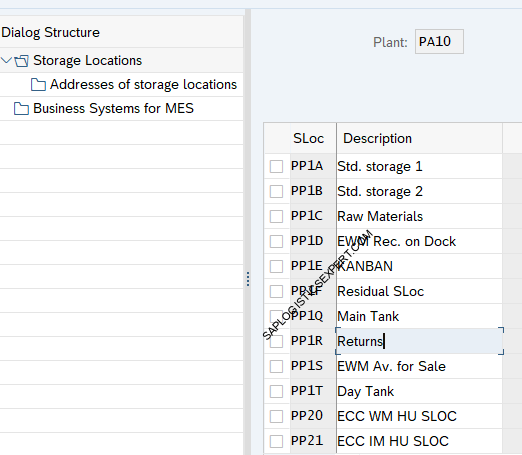

- Assign Purchasing organization to Plant

(PA10->PA10, PA20->PA10, PP10->PP10)

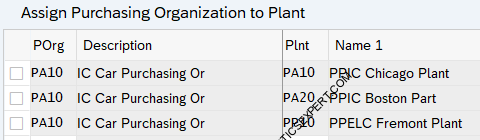

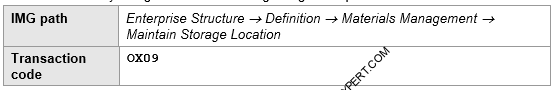

- Create Storage Location

(SLOCs are created, Check respective section below for details)

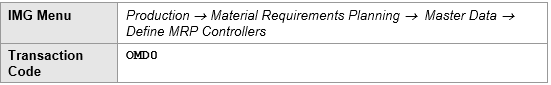

- Create MRP Controller

(Check respective section below for details)

- MM Organization Structure in Pictorial Form

Configure S4 HANA MM Organization Structure

Create Purchasing Groups

A key for a buyer or group of buyers responsible for certain purchasing activities. A purchasing organization can be divided into several purchasing groups that are responsible for different operational areas.

Below Purchasing Groups are created for our business

Create Purchasing Organization

A purchasing organization is responsible for the purchasing activities of one plant.

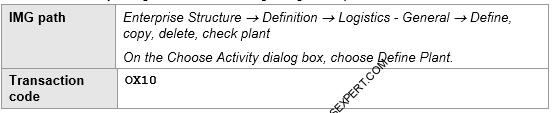

Assign Purchasing Organization to Company Code

We assign the Purchasing organization to company code based on the strategic purchasing.

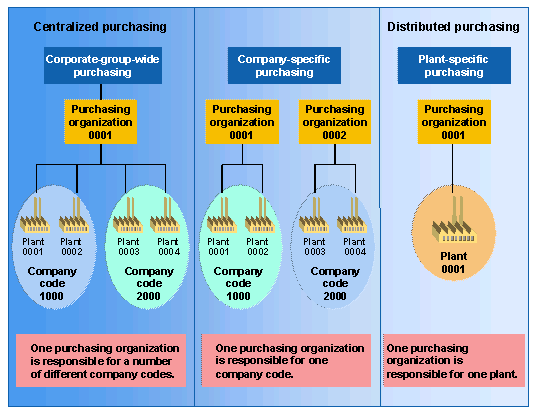

Three form of purchasing is possible in SAP

Corporate-group-wide purchasing

A purchasing organization is responsible for the purchasing activities of different company codes.

Note : In this case, we do not assign a company code to the purchasing organization, but specify the company code concerned for each individual purchasing transaction. In configuration we assign the plants from different company codes to the purchasing organization.

Company-specific purchasing

A purchasing organization is responsible for the purchasing activities of just one company code.

Note : In this case, we assign a company code to the purchasing organization. The purchasing organization may procure only for this company code. We assign only plants of the company code concerned to the purchasing organization.

Plant-specific purchasing

A purchasing organization is responsible for the purchasing activities of one plant.

Note : In this case, we assign the plant and the company code of the plant to the purchasing organization. The purchasing organization may procure for this plant only

The below picture depicts the different ways of organizing purchasing function in the SAP System

Courtesy : SAP Help

For our Car business we will configure "Company Specific Purchasing" i.e. Separate purchasing organization will be responsible for separate company codes

Create Plant

The plant is an operating area or branch within a company.

The plant as an organizational structure works as follows:

- The plant is assigned to a single company code. A company code can have several plants.

- Several storage locations in which material stocks are managed can belong to a plant.

- A single business area is assigned to a plant and to a division.

- A plant can be assigned to several combinations of sales organization and distribution channel.

- A plant can have several shipping points. A shipping point can be assigned to several plants.

- A plant can be defined as a maintenance planning plant.

Created our three plants

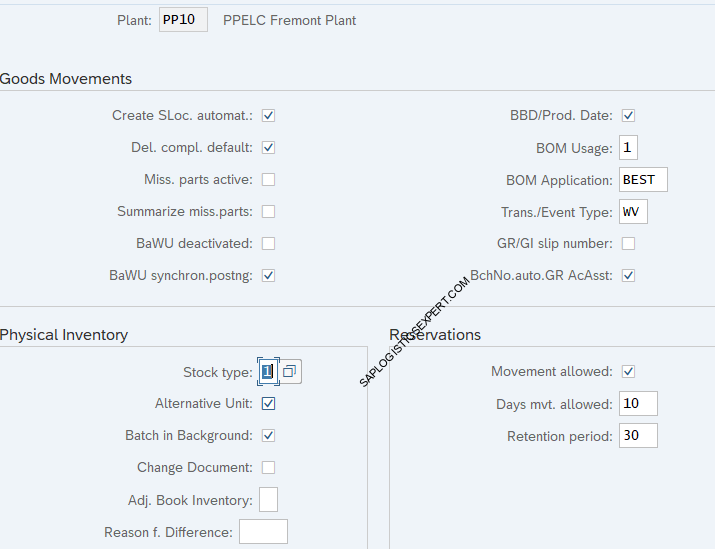

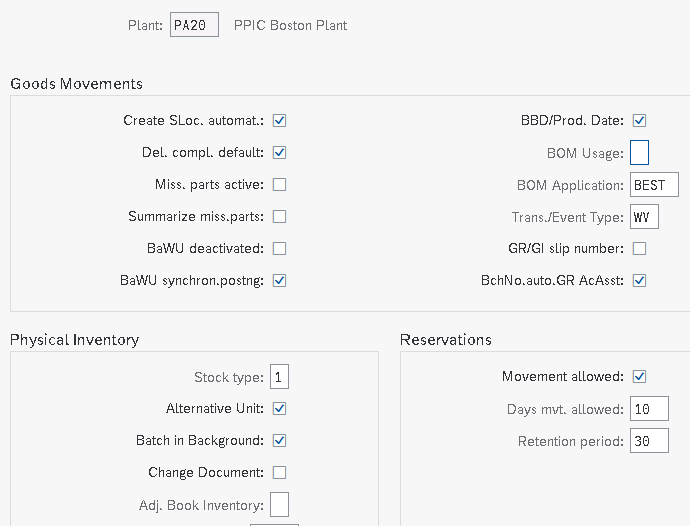

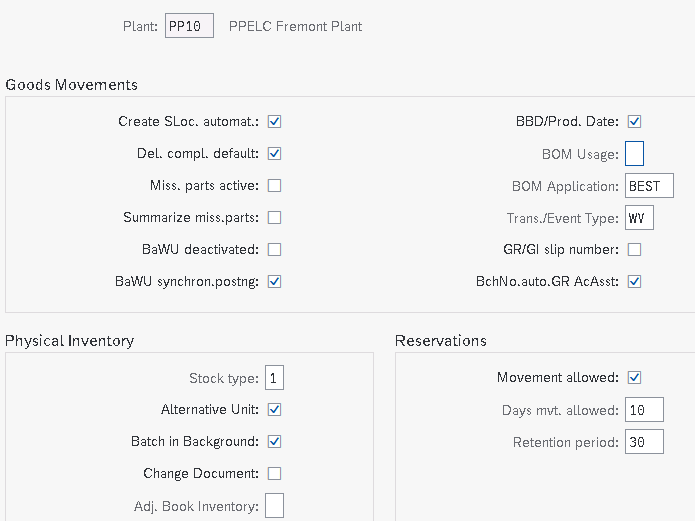

Define Plant Parameter

These are general Plant setting which is require for our three new plants.

Feel free to write if you need any help to understand any of this plant parameter.

Screenshot below is for one plant PP10. Similar parameter has been given to other two plants PA10 & PA20 too

We will review some of the important plant parameter

Automatic creation of storage location allowed

It Indicates that automatic creation of storage location data at the time of the first goods receipt is allowed.

Note : This should be allowed in the respective movement type also.

"Delivery completed" indicator

If this indicator is set, the system sets "delivery completed" indicator as a default value when a goods receipt is posted with reference to a purchase order or order .

Note : Quantity delivered should fall within the under/over-delivery tolerances.

Missing Parts Active

System check whether the material received is a missing part. If so, the system issues a warning and simultaneously sends a mail message to the MRP controller.

Note :Checking rules needs to be assigned to the transaction. Also missing parts checks and output determination functions have been set .

Check Best Before Date/Production Date

Indicates that the shelf life expiration date check at the time of goods receipts in the plant is active.

Note : For this , the expiration date check is active for the movement type & the minimum remaining shelf life has been defined in the material master record or in the purchase order

Automatic Batch no. assignment permitted for GR w. acct assgt

Indicates whether automatic batch number assignment is permitted when goods are received for a purchase order with account assignment for a material that is to be handled in batches

Assign Plant to Company Code

In this step, we assign each plant to a company code. A plant can only belong to one company code.

Assign IC car Plants to IC Car Company Code & Electrical Car Plant to Electrical Car Company Code

Note : To Check the configuration related to company code pleas check Finance Organization Structure 5 Minutes Guide

———————————————————————————————————————————-

Assign Sales Organization Distribution Channel to Plant

Electric Car Plant will serve Electrical car related sales area and IC car plant will serve to IC car sales area

Note : To check configuration related to Sales Organization and other SD related Configuration Please click HERE

Assign Purchasing Organization to Plant

Create Storage Location

A storage location is the place where stock is physically kept within plant.

Below SLOCs are created for all three plants

Create MRP Controller

The MRP controller is a person or a group of persons responsible for monitoring material availability.

Below MRP Controller are created for all our three plants

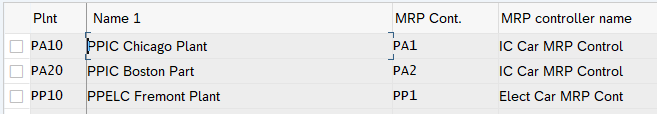

Create Material Groups

Below Material Groups Have been created

We have completed S4 HANA MM Organization Structure.

In the next Post we will configure S4 HANA Logistics Execution related Organization Structure.

Pic Courtesy : Building photo created by freepik – www.freepik.com

How To Create Purchasing Organization In Sap

Source: https://www.saplogisticsexpert.com/configure-sap-s4-hana-material-management-organization-structure-in-5-minutes/

Posted by: hiserotile1968.blogspot.com

0 Response to "How To Create Purchasing Organization In Sap"

Post a Comment